Related Products

What is a mold embryo?

Mold is an important tool and equipment for manufacturing industrial products, and mold blanks are a crucial part of mold manufacturing. In industrial manufacturing, mold blanks are widely used in various industries, such as automotive manufacturing, aerospace, electronic equipment, etc. This article will introduce the definition, classification, manufacturing process, and application fields of mold blanks.

1. Definition of mold blanks

Mold embryo refers to the basic component of a mold, which is the product of applying mold theory and technology to the actual manufacturing process. Mold blanks are usually made of metal materials, such as steel, aluminum alloys, etc. It has good wear resistance, corrosion resistance, and high strength, and can withstand complex machining processes and high-temperature and high-pressure environments.

2. Classification of Mold Embryos

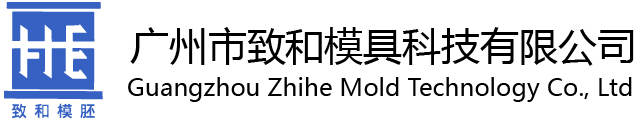

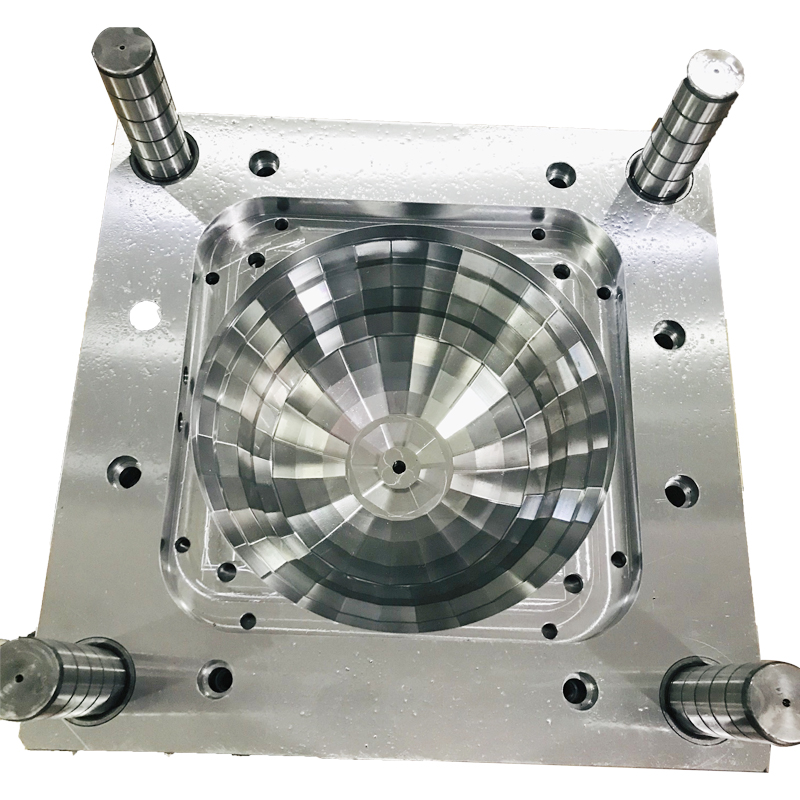

According to the shape and function of the mold, the mold embryo can be divided into various types. Common mold blanks include injection molding blanks, die-casting blanks, stamping blanks, etc. Injection molded parts are mainly used for the production of plastic products, die-casting molded parts are used for the production of metal products, and stamping molded parts are used for the processing of metal sheets.

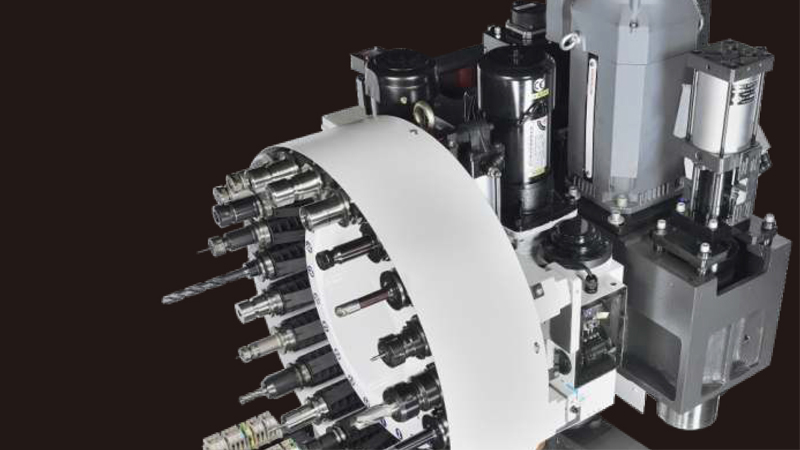

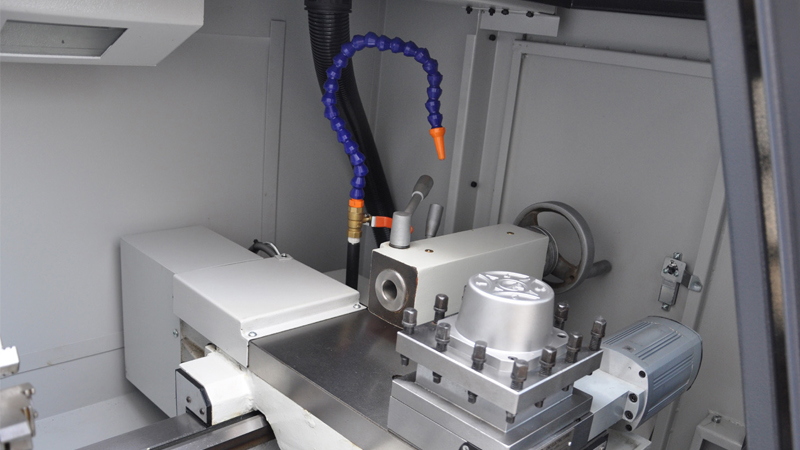

3. Manufacturing process of mold blanks

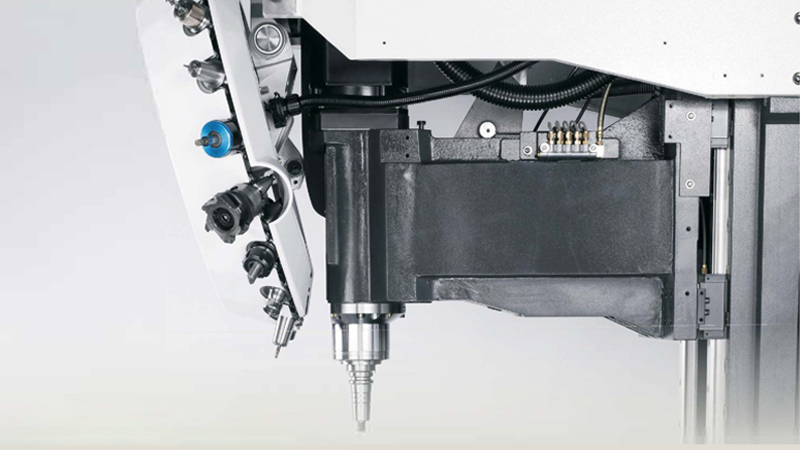

The manufacturing process of mold blanks can be divided into multiple steps. Firstly, it is the selection and preparation of materials, selecting suitable metal materials, and carrying out machining processes such as cutting and forging. Next is the precision machining of the mold preform, including milling, turning, grinding and other processes, to ensure that the mold preform meets the required dimensions and accuracy as designed. Finally, heat treatment and surface treatment are used to improve the hardness and wear resistance of the mold through quenching, tempering and other heat treatment processes. Surface treatment processes such as chrome plating and electroplating are also used to increase the surface smoothness and corrosion resistance of the mold.

4. Application fields of mold blanks

Mold blanks have a wide range of applications in various industrial manufacturing. In automobile manufacturing, mold blanks are used for the production of automotive components, such as engine blocks, body structures, etc. In the aerospace field, mold blanks are used for the production of aircraft components, such as wings, fuselage, etc. In the manufacturing of electronic devices, mold blanks are used for the manufacturing of products such as mobile phones and televisions. In addition, mold blanks are widely used in furniture manufacturing, daily necessities manufacturing, and other fields.

Summary:

As a crucial part of molds, mold blanks play an important role in industrial manufacturing. It has multiple types and diverse manufacturing processes, with a wide range of applications. Through continuous innovation and technological progress, the manufacturing process and quality of mold blanks have been continuously improved, providing reliable support for industrial manufacturing.

Previous: No More

Next: Mold manufacturers share with everyone the knowledge of mold processing