Related Products

Mold manufacturers share with everyone the knowledge of mold processing

In order to prevent damage and deformation during use, anti loosening measures should be taken for fastening parts to avoid accidental injury to operators. All types of parts on the mold should have sufficient strength and stiffness; It is not allowed for waste or workpiece missiles to occur during the processing, affecting the operator's attention and even injuring the operator. Additionally, it is important to avoid cutting hands with burrs on the punched parts. Authentic mold processing does not allow operators to have excessive movement amplitude during stamping operations to avoid posture that may cause instability of the body; Excessive and inaccurate actions are not allowed during homework. Strong noise and vibration during stamping should be avoided as much as possible. The design of mold embryo processing should indicate the weight of the mold on the overall drawing, which is convenient for installation and ensures safety.

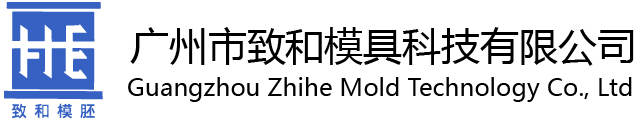

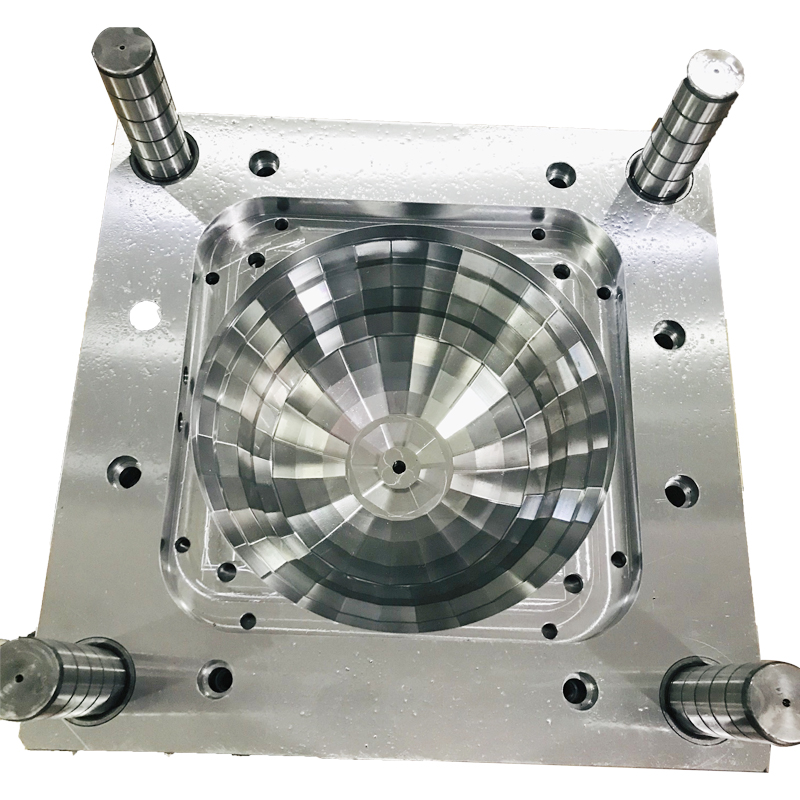

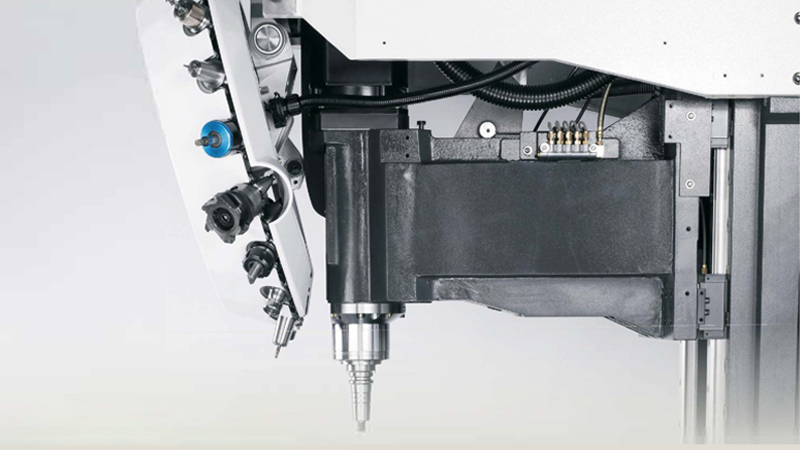

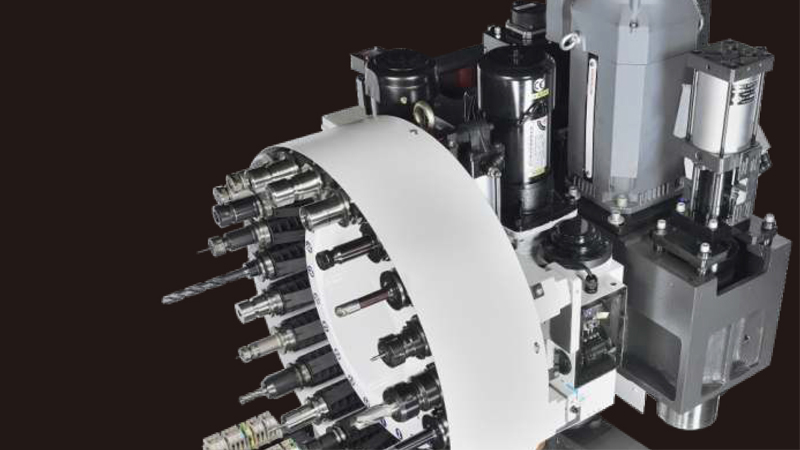

Parts weighing over 20 kilograms should be processed with lifting and handling measures to reduce labor intensity. When assembling and disassembling processed parts, it should be convenient and safe to avoid the possibility of gripping or cutting hands; The mold should be easy to collapse and store. Because the mold does not participate in forming, its shape does not change with the changes of the parts, but only depends on the size and structure of the parts. Therefore, the mold can be standardized, that is, the mold form is generally similar, only with changes in size and thickness. After standardization, it is very convenient to process. The mold factory can first process various sizes of mold parts (templates, guide pillars), etc, Then, according to the customer's needs, form a set of mold blanks; The most basic requirement for a standard mold is to smoothly open the mold.

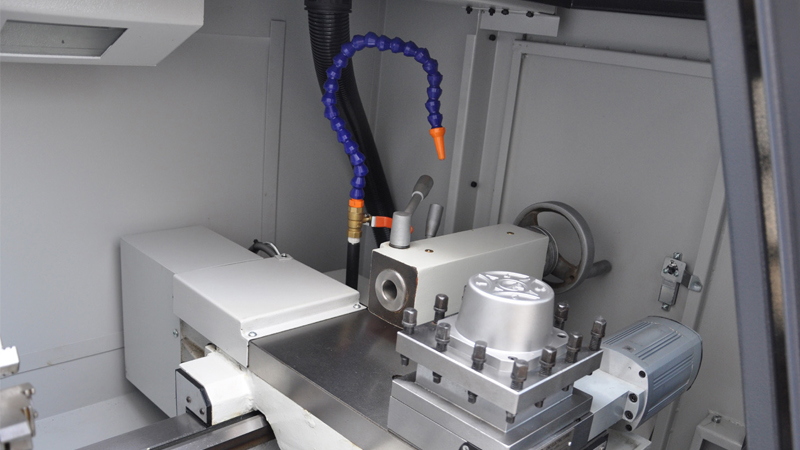

All types of parts in mold processing should have sufficient strength and stiffness to prevent damage and deformation during use. Fasteners should have anti loosening measures to prevent accidental injury to operators; The base of the mold facilitates the installation of the mold, providing support, protection, and connecting the key components (core) of the mold; The smoothness of mold opening is directly related to the precision of the four guide pillar holes. Authentic molds mainly focus on the production and full processing of mold frames, with dual color and multi-color molds as highlights. We are known for providing customers with one-stop services and product solutions

Previous: Mold processing steps and processes

Next: No More