Related Products

Mold processing steps and processes

Mold design: Firstly, it is necessary to design a suitable mold according to the product's requirements to ensure that the required components can be effectively processed. At this stage, it is necessary to consider the physical properties of the raw materials, especially their plasticity and deformation ability, to ensure the quality and performance of the mold.

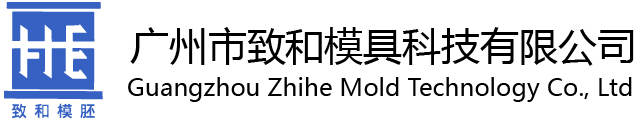

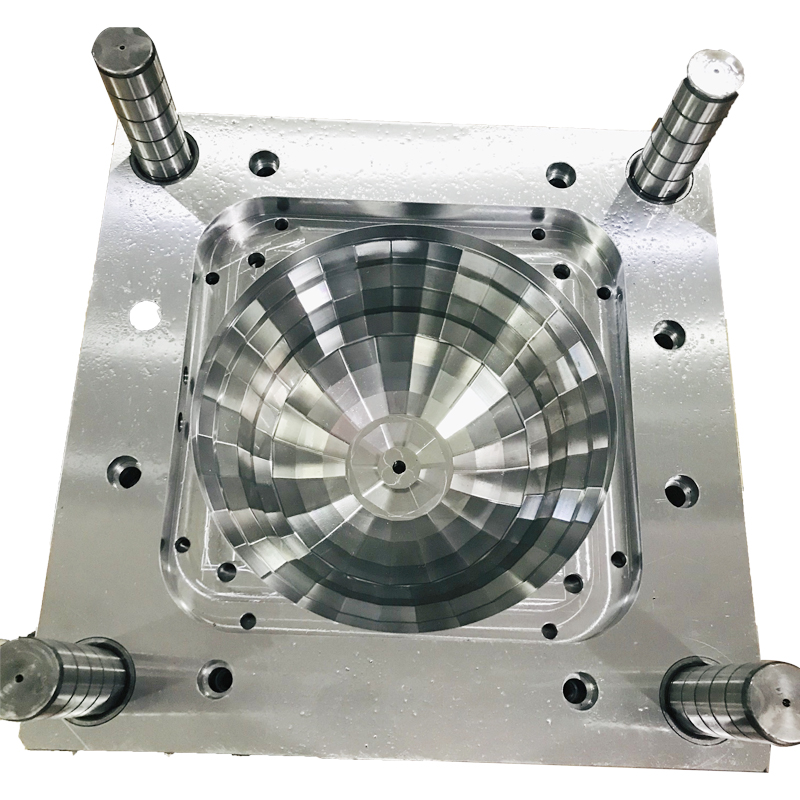

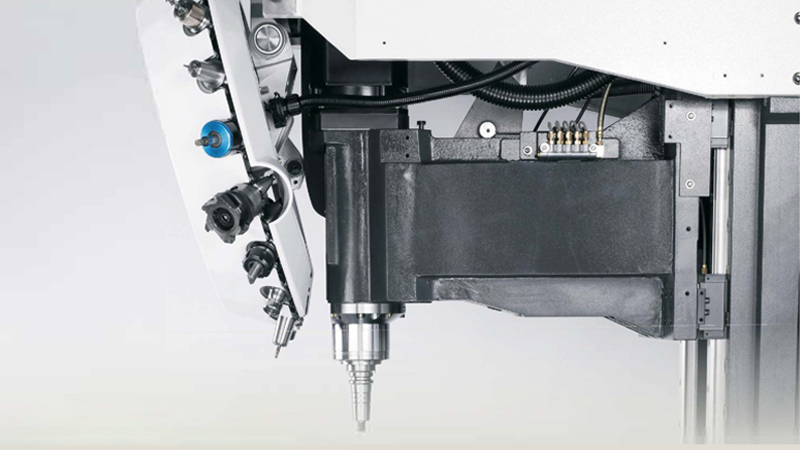

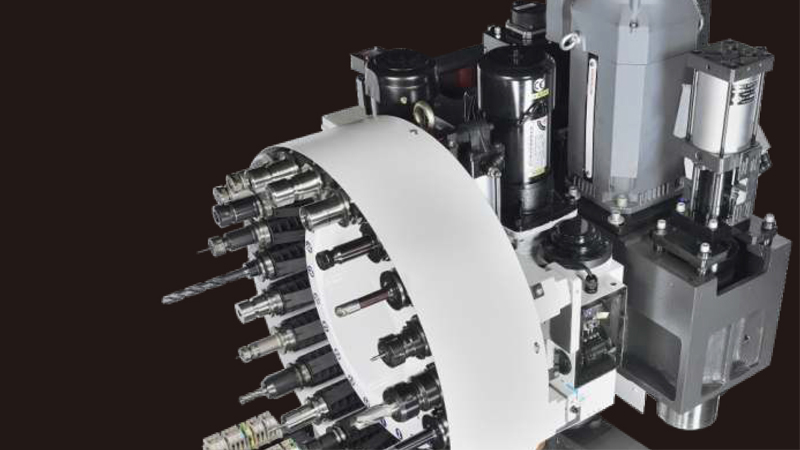

Mold manufacturing: This is the core process of mold embryo processing, usually using mechanical processing technology to manufacture molds. This may involve operations such as drilling, cutting, chamfering, and tilting to ensure that the mold has good machining performance and quality.

Material preparation: In order to ensure that the material of the mold can meet the required standards, a series of preparation processes are required, such as cutting, stamping, heat treatment, welding, polishing, etc.

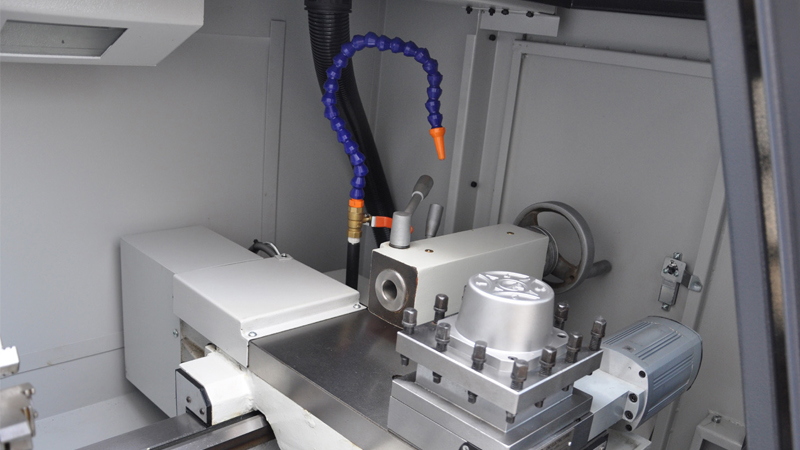

Mold processing: Combining the prepared mold with raw materials to perform part molding and processing. This step is the most critical operation as it directly affects the accuracy and quality of the finished parts.

Semi precision machining and precision machining: After mold processing, semi precision machining and precision machining are also required, which are processed separately for different working surfaces and details to achieve higher accuracy and surface quality.

Heat treatment: According to material and design requirements, heat treatment is applied to non-standard mold blanks to change their physical properties, improve the hardness and durability of the mold.

Surface treatment: Polish and chrome plated the surface of the mold to improve its corrosion resistance and aesthetics.

Inspection and Review: After each processing stage, inspection and review are required to ensure machining accuracy and quality.

Cleaning and treatment: Before proceeding to the next processing stage, it is necessary to perform cleaning treatment to maintain the cleanliness of the part surface.

Dimensional inspection: Use corresponding measuring tools to perform dimensional inspection on the processed parts, ensuring that they meet the design requirements.